Covering a story? Visit our page for journalists or call (773) 702-8360.

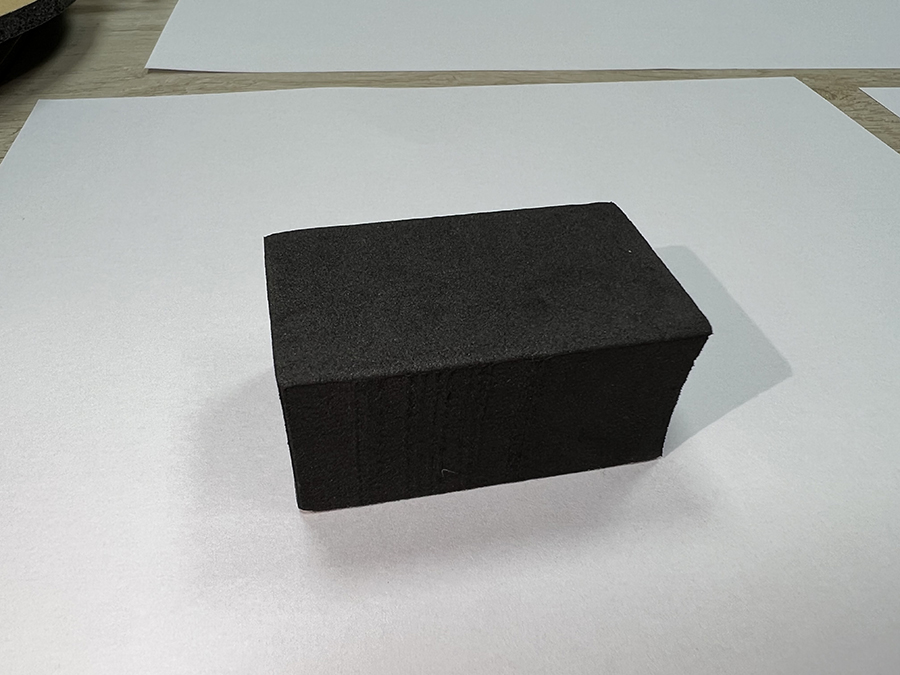

Scientists with the University of Chicago have discovered a way to create a material that can be made like a plastic, but conducts electricity more like a metal. Reinforced Ring

The research, published Oct. 26 in Nature, shows how to make a kind of material in which the molecular fragments are jumbled and disordered, but can still conduct electricity extremely well.

This goes against all of the rules we know about for conductivity—to a scientist, it’s kind of seeing a car driving on water and still going 70 mph. But the finding could also be extraordinarily useful; if you want to invent something revolutionary, the process often first starts with discovering a completely new material.

“In principle, this opens up the design of a whole new class of materials that conduct electricity, are easy to shape, and are very robust in everyday conditions,” said John Anderson, an associate professor of chemistry at the University of Chicago and the senior author on the study. “Essentially, it suggests new possibilities for an extremely important technological group of materials,” said Jiaze Xie (PhD’22, now at Princeton), the first author on the paper.

Conductive materials are absolutely essential if you’re making any kind of electronic device, whether it be an iPhone, a solar panel, or a television. By far the oldest and largest group of conductors is the metals: copper, gold, aluminum. Then, about 50 years ago, scientists were able to create conductors made out of organic materials, using a chemical treatment known as “doping,” which sprinkles in different atoms or electrons through the material. This is advantageous because these materials are more flexible and easier to process than traditional metals, but the trouble is they aren’t very stable; they can lose their conductivity if exposed to moisture or if the temperature gets too high.

But fundamentally, both of these organic and traditional metallic conductors share a common characteristic. They are made up of straight, closely packed rows of atoms or molecules. This means that electrons can easily flow through the material, much like cars on a highway. In fact, scientists thought a material had to have these straight, orderly rows in order to conduct electricity efficiently.

Then Xie began experimenting with some materials discovered years ago, but largely ignored. He strung nickel atoms like pearls into a string of of molecular beads made of carbon and sulfur, and began testing.

To the scientists’ astonishment, the material easily and strongly conducted electricity. What’s more, it was very stable. “We heated it, chilled it, exposed it to air and humidity, and even dripped acid and base on it, and nothing happened,” said Xie. That is enormously helpful for a device that has to function in the real world.

But to the scientists, the most striking thing was that the molecular structure of the material was disordered. “From a fundamental picture, that should not be able to be a metal,” said Anderson. “There isn’t a solid theory to explain this.”

Xie, Anderson, and their lab worked with other scientists around the university to try to understand how the material can conduct electricity. After tests, simulations, and theoretical work, they think that the material forms layers, like sheets in a lasagna. Even if the sheets rotate sideways, no longer forming a neat lasagna stack, electrons can still move horizontally or vertically—as long as the pieces touch.

The end result is unprecedented for a conductive material. “It’s almost like conductive Play-Doh—you can smush it into place and it conducts electricity,” Anderson said.

The scientists are excited because the discovery suggests a fundamentally new design principle for electronics technology. Conductors are so important that virtually any new development opens up new lines for technology, they explained.

One of the material’s attractive characteristics is new options for processing. For example, metals usually have to be melted in order to be made into the right shape for a chip or device, which limits what you can make with them, since other components of the device have to be able to withstand the heat needed to process these materials.

The new material has no such restriction because it can be made at room temperatures. It can also be used where the need for a device or pieces of the device to withstand heat, acid or alkalinity, or humidity has previously limited engineers’ options to develop new technology.

The team is also exploring the different forms and functions the material might make. “We think we can make it 2-D or 3-D, make it porous, or even introduce other functions by adding different linkers or nodes,” said Xie.

Other authors on the paper include University of Chicago graduate students Norman Zhao, Garrett Grocke, Ram Itani, Baorui Cheng, Tengzhou Ma (PhD'21, now at Applied Materials), Simon Ewing (PhD’22, now at Intel) and Jan-Niklas Boyn (PhD’22, now at Princeton); postdoctoral researcher Xiaotong Sun; UChicago Director of X-ray Research Facilities Alexander S. Filatov; Himchan Cho (formerly a postdoctoral researcher at UChicago, now at Korea Advanced Institute of Science and Technology); UChicago Profs. Shrayesh N. Patel, Dmitri V. Talapin, Jiwoong Park, and David A. Mazziotti; and Zhihengyu Chen and Prof. Karena Chapman of Stonybrook University.

Citation: “Intrinsic Glassy-Metallic Transport in an Amorphous Coordination Polymer.” Xie et al, Nature, Oct. 26, 2022.

Funding: Army Research Office, a directorate of U.S. Army Combat Capabilities Development Command Army Research Laboratory; U.S. Department of Energy; National Science Foundation.

Get more with UChicago News delivered to your inbox.

Bozhi Tian and his laboratory at the University of Chicago are taking…

University of Chicago chemist Weixin Tang receives 2022 Packard…

Stainless Steel Hardware 5801 S. Ellis Ave., Suite 120, Chicago, IL 60637